New here? Free $20 coupon.

| No. | Item | Manufacturing Capabilities | Illustration |

|---|---|---|---|

| 1 | Material | FR-4 (Fiberglass) | Please check below Material List |

| 2 | Number of Layers | 1 Layer, 2 Layers, 4 Layers, 6 Layer, 8 Layers,10 Layers | Standard stackup for multilayer pcbs. |

| 3 | TG Grade | TG130~140, TG150~160, TG170~180 | |

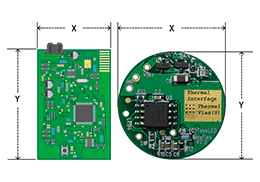

| 4 | Max PCB Size | 1 layer & 2 layers: 1200*300mm or 600*500mmMulti-layers: 600*500mm |  |

| 5 | Min PCB Size | 5mm*5mm | |

| 6 | Board Size Tolerance(Outline) | ±0.2mm(CNC routing)±0.5mm(V-scoring) | |

| 7 | Surface Finish | HASL with lead, HASL lead free, Immersion gold(ENIG), OSP, Hard gold, ENEPIG, Immersion silver (Ag), None |  |

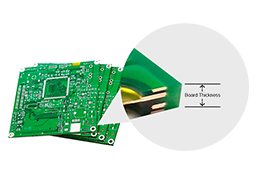

| 8 | Board Thickness | 1 Layer/2 Layers: 0.2~2.4mm4 Layers: 0.4~2.4mm6 Layers: 0.8~2.4mm8 Layers: 1.0~2.4mm10 Layers: 1.2~2.4mm Note: Customized PCB thickness and Layer stackup are acceptable. |

|

| 9 | Board Thickness Tolerance | Thickness≥1.0mm: ±10%Thickness<1.0mm: ±0.1mm Note: Normally “+ Tolerance” will occur due to PCB processing steps such as electroless copper, solder mask and other types of finish on the surface. |

|

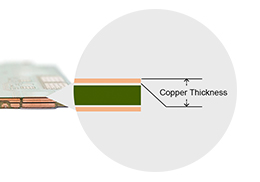

| 10 | Outer Layer Copper Thickness | 1oz/2oz/3oz(35μm/70μm/105μm) Note: 2ozPCB thickness≥1.2mm,Via size≥0.25mm,Min Track/Spacing≥0.15mm 3ozPCB thickness≥2.0mm,Via size≥0.3mm,Min Track/Spacing≥0.2mm |

|

| 11 | Inner Layer Copper Thickness | 1oz/1.5oz(35μm/50μm) | |

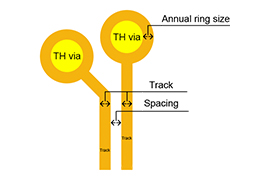

| 12 | Outer layer Min track/spacing | ≥3mil |  |

| 13 | Inner layer Min track/spacing | ≥4mil | |

| 14 | Annular Ring Size | ≥0.13mm | |

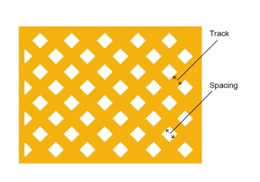

| 15 | Grid Line track/spacing | ≥0.2mm |  |

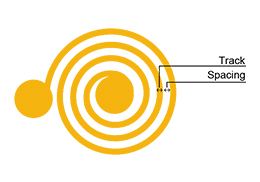

| 16 | Coil board Line track/spacing | ≥0.2mm |  |

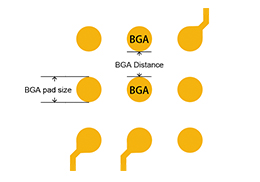

| 17 | BGA pad size | ≥0.25mm |  |

| 18 | BGA Distance | ≥0.12mm | |

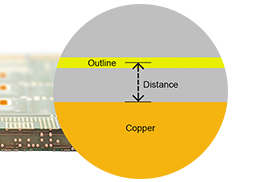

| 19 | Board Outlines | Track to Outline: ≥0.3mm Trace to V-cut line: ≥0.4mm |  |

| 20 | Finished Hole Size Tolerance | ±0.08mm |  |

| 21 | Finished Hole Diameter(CNC) | 0.2mm~6.3mm 1. PCB Thickness=2.0mm, Minhole size is 0.3mm2. PCB Thickness=2.4mm, Min hole size is 0.4mm3. Copper Thickness=2OZ, Min hole size is 0.25mm4. Copper Thickness=3OZ, Min hole size is 0.3mm |

|

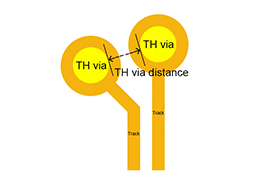

| 22 | TH Via Distance | Same nets: 0.15mmDifferent net: 0.25mm | |

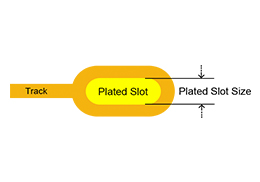

| 23 | Plated Slot Size | ≥0.5mm Note:L:W=2.5: 1 (Should be 2.5:1 or higher. If it is less than this, the holes may be misaligned.) If you can’t draw a long hole in your design, you can draw a continuous round hole and it will be regarded as a long hole. Also, it is okay to draw the oblong hole in Profile Layer instead of Drilling Layer. |

|

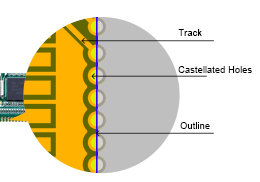

| 24 | Castellated Holes | ≥0.6mm |  |

| 25 | Non-Plated Holes | ≥0.8mm |  |

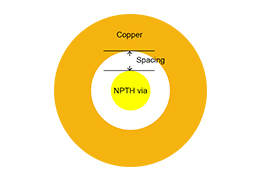

| 26 | NPTH to Copper Line | ≥0.2mm | |

| 27 | Soldermask | Green, Red, Yellow, White, Black, Blue, Purple, Matte Green,Matte Black,None |  |

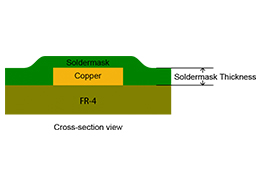

| 28 | Soldermask Thickness | 20~30um | |

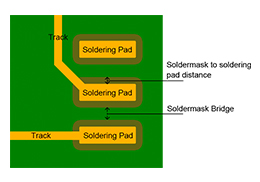

| 29 | Soldermask Bridge | Green: ≥0.1mmOthers: ≥0.15mm |  |

| 30 | Soldermask to soldering pad distance | ≥0.05mm | |

| 31 | Silkscreen | White, Black, Yellow, None |  |

| 32 | Minimum Character Width(Legend) | ≥0.15mm Note: Characters of less than 0.15mm wide will be too narrow to be identifiable. |

|

| 33 | Minimum Character Height (Legend) | ≥0.75mm Note: Characters of less than 0.8mm high will be too small to be recognizable. |

|

| 34 | Character Width to Height Ratio (Legend) | 1: 5 (In PCB silkscreen legends processing, 1:5 is the most suitable ratio) | |

| 35 | Silkscreen to Soldering Pad Distance | ≥0.1mm | |

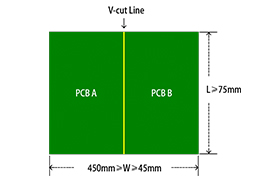

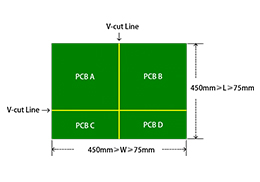

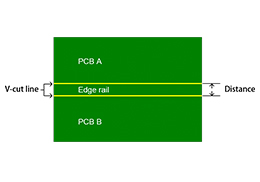

| 36 | V-cut Line | ≥70mm Note:PCB thickness≥0.6mmDetails refer to right side picture |

|

| 37 | V-cut Line Distance | ≥3.5mm |  |

| 38 | Distance betwen Board to Board | ≥0.8mm |  |

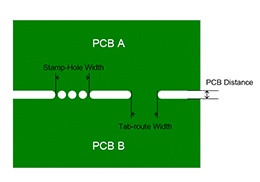

| 39 | Stamp-hole Width | ≥2.0mm Note: PCB size and thickness are subject to review by PCBGOGO. |

|

| 40 | Tab-route Width | ≥1.6mm Note: PCB size and thickness are subject to review by PCBGOGO. |

|

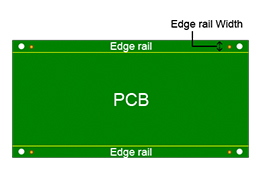

| 41 | Edge Rail | ≥3.5mm Note: If choosing panel by PCBGOGO, we will add 5mm edge rails on both sides by default. |

|

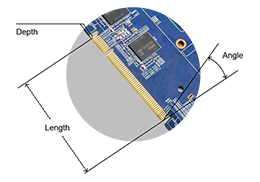

| 42 | Gold Finger | Bevelling Angle: 30~45°Depth: ≥1mmLength: 45mm~280mm Note: Board thickness≥1.2mm |

|

| 43 | Special Specification | Impedance controlCustom Layer StackupInterstitial Via Hole(IVH)Via in padVia filled with resinCountersinks/CounterboresCarbon MaskHalogen-FreeZ-axis millingEdge PlatingOthers |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.