New here? Free $20 coupon.

PCBA Test

Visual inspection: general quality check.

FAI: full quality check applied to the first PCB to pass through all stages of production.

X-ray Inspection: checks for BGAs, QFN and bare circuit boards.

AOI Testing: checks for solder paste, 0201 components, missing components and polarity.

3D AOI Testing: checks for missing and misplaced SMT components in three dimensions.

3D SPI Testing: measures the precise volume of solder paste for SMT assembly.

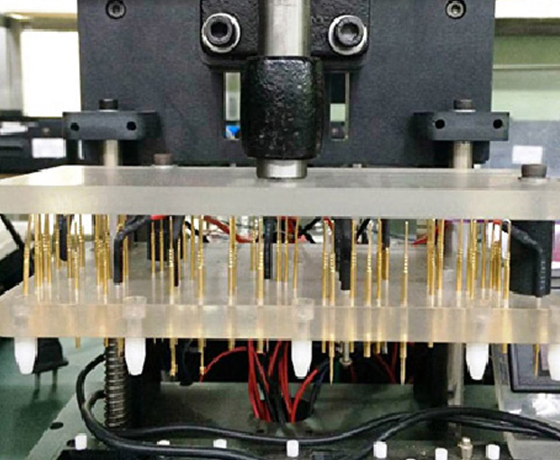

ICT (In-Circuit Test)

Functional test (Following your test procedures)

• Line width violations

• Spacing violations

• Excess copper

• Missing pads

• Cut traces or pads

• Hole breakage

• Although a costly fixture is required, ICT covers 100% testing so that all power and ground shorts are detected.

• ICT testing does power up testing and eliminates customer debug needs to almost ZERO.

• ICT does not take a very long time to perform, for example if flying probe takes 20 minutes or so, ICT for the same time might take a minute or so.

• Checks and detects shorts, opens, missing components, wrong value components, wrong polarities, defective components and current leakages in the circuitry.

• Highly reliable and comprehensive test catching all manufacturing defects, design faults, and flaws.

• Testing platform is available in Windows as well as UNIX, thus making it slightly universal for most testing needs.

• Test development interface and operating environment is based on standards for an open system with fast integration into an OEM customer’s existing processes.

• ICT is the most tedious, cumbersome, and expensive type of testing. However, ICT is ideal for mature products requiring volume production. It runs the power signal to check voltage levels and resistance measurements at different nodes of the board. ICT is excellent at detecting parametric failures, design related faults and component failures.

• X-ray inspection/testing

• Microsection Test

• contamination test

• Solderability Test

• Time Domain Reflectometer Test (TDR)

• peel test